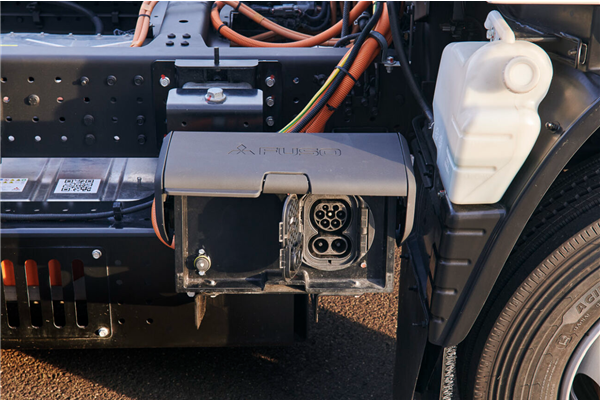

The Next Generation eCanter 8.55 t is the purely electrically powered alternative when it comes to somewhat weightier transport tasks in addition to local zero emissions.

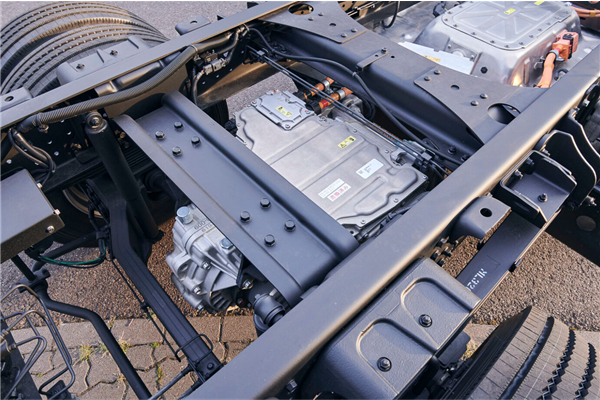

With a wheelbase of 3,400 mm and a range of up to 140 km */** (M battery), for example, it has a maximum chassis payload of 5,110 kg and can also offer high maximum axle loads – 3,400 kg on the front axle and 6,000 kg on the rear axle. FUSO also equips it ex works with optional mechanical power take-offs (mPOT), which supply power units such as tipping hydraulics.

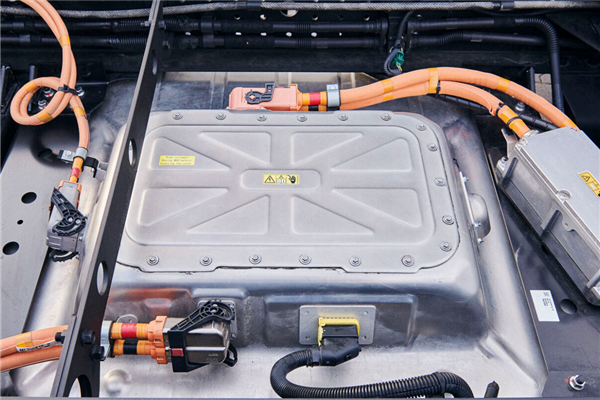

FUSO offers the Next Generation eCanter 8.55 t in four different wheelbases – 3,400 mm, 3,850 mm, 4,450 mm and 4,750 mm – and equips it with battery packs in M (up to 140 km range) and L (up to 200 km range) – depending on the wheelbase selected. In its largest variant (4,750 mm wheelbase) and with a body length of 7.2 m, the Next Generation eCanter has maximum load volume with up to 15 pallet spaces.

In addition, the Next Generation eCanter 8.55 t is not only very agile to drive, but thanks to its compact dimensions, as is the case with all FUSO Canters, absolute manoeuvrability is of course always included, regardless of the configuration.